Prepainted Color Coated Galvanized/ Galvalume Zinc Coated Steel Coil for Corrugated Sheet

Hot-rolled steet/coil from finishing the last hot steel strip mill out through laminar flow cooling to the set temperature, which consists of the winder coil, steel coil after cooling, according to the different needs of users, with different finishing line (flat, straightening, transverse or longitudinal cutting, inspection, weighing, packaging and logo, etc.) and become a steel plate, flat roll and longitudinal cutting steel strip products. Because hot rolled steel products have high strength, good toughness, easy processing and good weldability and other excellent properties, it is widely used in shipbuilding, automobile, bridge, construction, machinery, pressure vessel and other manufacturing industries.

| Ame | 0.17mm High Quality Galvanized Steel Coil for Building Material |

| Standard | AISI,ASTM,BS,DIN,GB,JIS |

| Material | SPCC/SPCD/SPCE/ST12-15/DC01-06/DX51D/JISG3303 |

| Thickness | 0.12mm-2.0mm |

| Width | 600-1500mm |

| Tolerance | "+/-0.02mm |

| Surface treatment: | unoil,dry,chromate passivated, non-chromate passivated |

| Coil ID | 508mm/610mm |

| Coil Weight | 3-5 tons |

| Technique | Cold rolled |

| Package | seaworthy package |

| Certification | ISO 9001-2008,SGS,CE,BV |

| MOQ | 20 TONS (in one 20ft FCL) |

| Delivery | 15-20 days |

| Monthly Output | 10000 tons |

| Description | The cold rolling reduces the thickness of the steel and at the same timechanges the mechanical properties of the steel. Cold rolled steel must be further processed,as the steel will react with water in the air and form rust. In most cases,it is covered with a thin layer of oil to prevent oxygen reacting with surface. The steel coils can be annealed (heated in a controlled atmosphere)to make the steel more formable (cold rolled annealed) or further processed on the metallic coating line, with a coating of either zinc (galvanized) or zincaluminium alloy applied. Cold rolled steel is available in a range of grades, each with a range of properties for differing applications. |

| Payment | 30%T/T in advanced+70% balanced;irrevocable L/C at sight |

| Remarks | Insurance is all risks and accept the third party test |

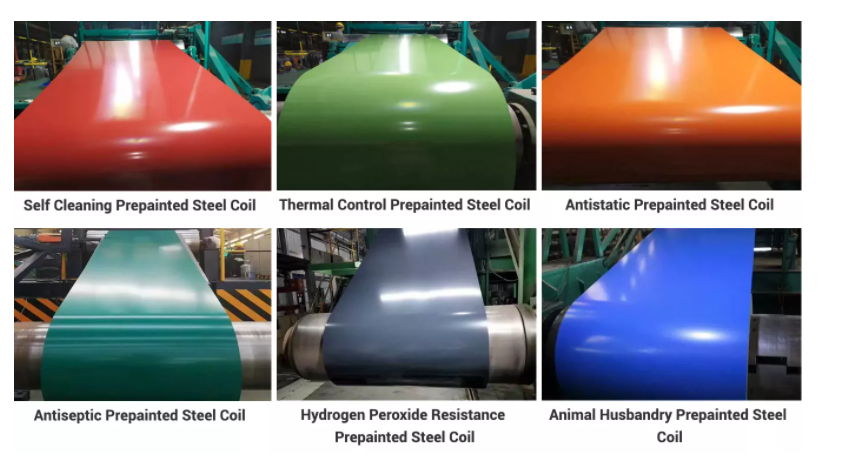

Polyester (PE): Good adhesion, rich colors, wide range in formability and outdoor durability, medium chemical resistance, and low cost.

Silicon modified polyester(SMP): Good abrasion resistance and heat resistance, as well as good external durability and

chalking resistance, gloss retention, general flexibility, and medium cost.

High Durability Polyester(HDP): Excellent color retention and anti-ultraviolet performance, excellent outdoor durability and anti-pulverization, good paint film adhesion, rich color, excellent cost performance.

Polyvinylidene Fluoride(PVDF): Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance, good moldability, stain resistance, limited color, and high

cost.

1.Good durability and long life compared with galvanized steel.

2.Good heat resistance, less discoloration at high temperature than galvanized steel.

3.Good thermal reflectivity.

4.Processability and spraying performance similar to galvanized steel.

5.Good welding performance.

6.Good performance-price ratio, durable performance and extremely competitive price.

01.Advanced equipment Three ppgi / ppgl production lines, using the most advanced equipment in China, a plant area of 30,000 square meters.

02.High-quality base steel We choose high-quality raw materials. Our base steel comes from Baosteel, Shougang, etc., and our coating materials come from Nippon, Aksu and other well-known international brands.

03.Output steel coils with a monthly output of about 5000-10000 tons, and have sufficient inventory.

04.Quality inspection The implementation of strict quality inspection standards, products comply with ISO, SGS international standards, to ensure 100% compliance with customer requirements.

05.Fast delivery Advanced production management process, from production to delivery, efficient and fast.