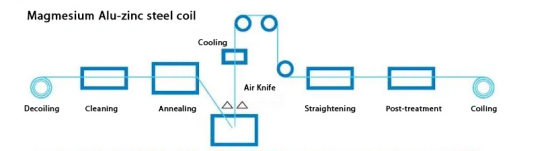

Hot Dipped Zn-Al-Mg Magnesium Zinc Coated Aluminium Alloy Steel Coil

Applications of High quality Zn-Al-Mg Zinc aluminum magnesium alloy coating steel coil

Zinc aluminum magnesium coil is added with Al, Mg, Si to improve the corrosion resistance. In addition to the previous adding Al, it is also added Mg and Si so that rust effect can be improved obviously. Si improves the corrosion resistance of the coating layer containing Al while further improving the corrosion effect by the combined action with Mg.

This Zinc Aluminum Magnesium Alloy Coated Sheet is widely used in construction, road protection, three-dimensional parking lot, storage equipment, automotive electromechanical equipment and other metal forming areas. It can manufacture all kinds of steel parts, corrosion-resistant parts, keel ceilings, perforated plate, cable tray. Where the use of hot-dip galvanized steel or hot-dip galvanized 5% aluminum alloy steel components after using zinc aluminum magnesium steel coil will be able to achieve better corrosion resistance.

| Product Name | Zinc Aluminum Magnesium Steel Coil |

| Coil ID | 508 / 610mm |

| Coil Weight | 3-5 Tons |

| Monthly Output | 10000 tons |

| MOQ | 25 tons or one container |

| Hardness | Soft hard(60), medium hard(HRB60-85), full hard(HRB85-95) |

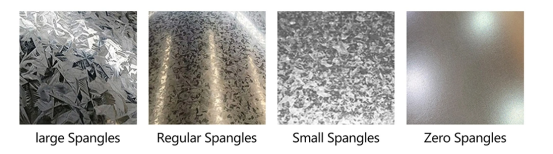

| Surface structure | Regular spangle, Minimum spangle, Zero spangle, Big spangle |

| Surface treatment | Chromated/Non-Chromated, Oiled/Non-oiled, Skin pass |

| Payment Terms | T/T, LC, O/A, DP |

| Delivery Time | 30 days |

1. Extraordinary corrosion resistance

2. Excellent alkali resistance

3. Inclusion has self-heating function, good corrosion resistance

4. Good processing performance, shell has excellent wear resistance and scratch resistance

1.Contact us with your detailed inquiry, you will be replied within 24 hours.

2.You are promised to obtain the best quality, price and service.

3.Wide excellent experiences with after-sale service.

4.Every process will be checked by responsible QC which insures every product's quality.