Hot Dip Galvanized steel sheet in coil DX51D z40 z80 z180 z275 High strength S280GD S320GD+Z GI zinc coated steel coil/strip

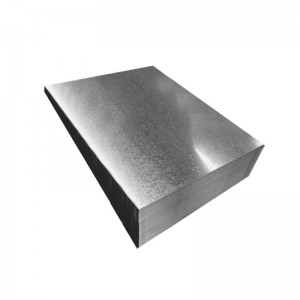

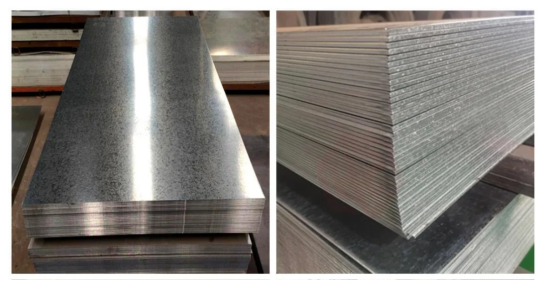

Electro-galvanized Steel Sheet

Electro-galvanizing, also known as cold galvanizing, uses electrolysis to form a uniform and dense layer on the surface of the metal. The anti-corrosion zinc layer can protect steel parts from oxidation corrosion. Also, it can meet decorative purposes. But the zinc layer of the electro-galvanizing steel sheet is only 5-30 g/m2. So its corrosion resistance is not as good as hot-dip galvanized sheets.

Difference Between Hot-Dip and Electro-galvanized Steel Sheets

Anti-corrosion

The zinc coating thickness is one of the most important factors matters corrosion resistance. The greater the zinc layer thickness, the better the corrosion resistance. Generally, the thickness of hot-dip zinc coating is more than 30 g/m2, or even as high as 600 g/m2. While the electro-galvanized zinc layer is only 5~30 g/m2 thick. So the former steel sheet is much more corrosion resistant than the latter one. At Wanzhi Steel, the maximum zinc layer is 275 g/m2 (z275 galvanized steel sheet).

Method of Operation

The hot-dip galvanized steel sheet is galvanized in a molten zinc bath at about 500 degrees, while the electro-galvanized steel sheet is processed at room temperature by electroplating or other methods. That's why electro-galvanizing also refers to the cold galvanizing process.

Surface Smoothness & Adhesion

The surface of the electro-galvanized steel sheet looks smoother than hot-dip galvanized sheets. But its adhesion is not as good as that of the hot-dip galvanized sheet. If you want only one side galvanized, you can choose the electroplating method. However, if adopting hot-dip galvanizing, both sides are coated with a zinc layer fully.

| Thickness | 0.12-5mm |

| Standard | AiSi,ASTM,bs,DIN,JIS,GB |

| Width | 12-1500mm |

| Grade | SGCC/CGCC/TDC51DZM/TDC52DTS350GD/TS550GD |

| Coating | Z40-Z275 |

| Technique | Coled Rolled Based |

| Coil Weight | 3-8 Tons |

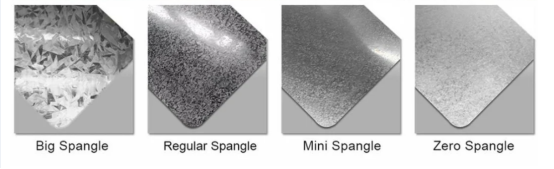

| Spangle | Zero.minimum .Regular Big Spangle |

| Commodity | Corrugated Roofing Sheet | |||

| Product | Galvanized Steel | Galvalume Steel | Prepainted Steel (PPGI) | Prepainted Steel (PPGL) |

| Thickness (mm) | 0.13 - 1.5 | 0.13 - 0.8 | 0.13 - 0.8 | 0.13 - 0.8 |

| Width(mm) | 750 - 1250 | 750 - 1250 | 750 - 1250 | 750 - 1250 |

| Surface treatment | Zinc | Aluzinc coated | RAL color coated | RAL color coated |

| Standard | ISO, JIS, ASTM, AISI, EN | |||

| Grade | SGCC, SGHC ,DX51D ; SGLCC,SGLHC; CGCC,CGLCC | |||

| Width(mm) | 610 - 1250mm (after corrugated)Raw material width 762mm to 665mm (after corrugated) Raw material width 914mm to 800mm (after corrugated) Raw material width 1000mm to 900mm (after corrugated) Raw material width 1200mm to 1000mm (after corrugated) |

|||

| Shape | According to different application requirements, the profiled steel sheet can be pressedinto a wave type, a T type, a V type, a rib type and the like. | |||

| Color coating (Um) | Top: 5 - 25m Back: 5 - 20m or as client's requirement | |||

| Paint Color | RAL code No. or customer' color sample | |||

| Surface treatment | Chromed passivation, anti-finger print, skinpassed. Ral color.every piece surface can be painted logo as customer requirement | |||

| Pallet weight | 2 - 5MT or as client's requirement | |||

| Quality | Softy, half hard and hard quality | |||

| Supply Ability | 30000 Tons/month | |||

| Price Item | FOB, CFR, CIF | |||

| Payment terms | T/T, L/C at sight | |||

| Delivery time | 15 - 35days after confirmed order | |||

| Packaging | Export standard, seaworthy | |||

1.Q: Can we visit factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

2.Q: Can provide OEM/ODM service?

A: Yes. Please feel free to contact us for more details discuss.

3.Q: What product information do I need to provide?

A:One is 30% deposit by TT before production and 70% balance against copy of B/L; the other is Irrevocable L/C 100% at sight.

4.Q: Can you provide sample?

A: The sample could can provide for customer with free, but the freight will be covered by customer account. The sample freight will be returned to customer account after we cooperate.

5.Q: How to pack the products?

A: The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It can effectively protect products from corrosion during ocean transportation.