Factory Nm360 Nm400 Nm450 Nm Hardox400, Hardox500, Nm400, Nm500, Xar400, Xar500 Abrasion/Wear Resistant Steel Plate Wear Resistant Steel Plate Nm360/400/450/500

Rolling Process Flow ChartReheating Furance+High-pressure Water Descaling+Edger Mill+Roughing Mill+Finishing Mill+Accelerated cooling+Hot Leveler+Marking and Spray Printing+Cooling Bed+On-line UT+Crop Shear+Double-side Trimming Shear+Cut-to-length Shear+Measurement+Marking and Spray Printing+Cold Leveler/Heat treatment

Heat-Treatment Flow ChartPlate+Shot Blasting+Quenching Furance+Quenching Machine+Tempering Furance+Warm Leveler+Cooling Bed+Cutting+Cold Leveler+Finishing&Packaging

Thickness and WidthThickness:4.5mm-150mm

Width:1600mm-4100mm

Main Grade Germany:XAR400,XAR450,XAR500,XAR600,Dillidur400,Dillidur500

Belgium:QUARD400,QUARD450,QUARD500

France:FORA400,FORA500,Creusabro4800,Creusabro8000

Baosteel:B-HARD360,B-HARD400,B-HARD450,B-HARD500

HBIS:NM360,NM400,NM450,NM500

Finland:RAEX400,RAEX450,RAEX500

Japan:JFE-EH360,JFE-EH400,JFE-EH500,WEL-HARD400,WEL-HARD500

Chemical Composition&Property

Cerifications

9 Classification Society

ISO 9001 Certified

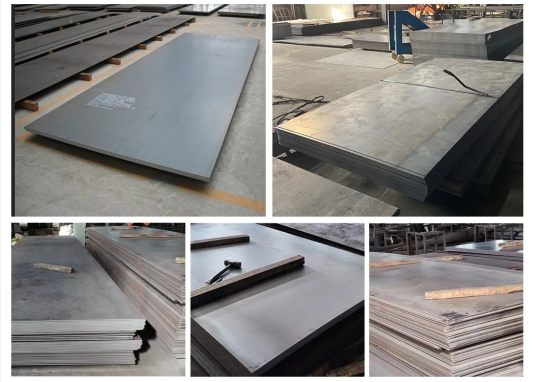

Packaging&Shipping

Seaworthy packaging by container or bulk cargo vessel

Delievery time:stock size within 7days;new material within 40days

Our services

We can cut steel plate according to customer's requriement or drawing,packaging according to customers' request

Application

By adopting the combined chemical composition design of low carbon,low sulfur,low phosphorous and micro-alloy,by applying the offline quenching and other advanced automation technologies,our wear resistant(Abrasion Resisant) plate are popular at home and abroad. Mainly used for thermal Power plant,Coal Mines ,Cement Mills,Loading Machinery,Mining Machinery,Project Machinery.Metallurgical Machinery,Wear resistant plate also can be applied in Sand Mill Cylindrical Shell, Vane, Mechanical Parts used in yard and port, Bearing Structure Parts etc.

| Grade | Size(mm) | RP0.2(Mpa) | Rm(Mpa) | A50(%) | AKV,(ºC) | KV2(J) | HBW | ||

| NM400 | 100 | 1233 | 1337 | 15 | -20 | 35 | 37 | 42 | 415 |

| NM450 | 60 | 1345 | 1434 | 9.5 | -20 | 72 | 59 | 58 | 455 |

| NM500 | 50 | 1608 | 1706 | 10.5 | -20 | 43 | 50 | 45 | 495 |

| XCHD400 | 35 | 1025 | 1161 | 17.5 | -40 | 52 | 45 | 40 | 413 |

| XCHD450 | 30 | 1281 | 1400 | 10.5 | -40 | 45 | 48 | 52 | 453 |

| XCH500 | 6 | 1465 | 1529 | 13.5 | -40 | 24 | 24 | 22 | 515 |

Q1: Why choose us?

A: Our company, as an internationally experienced and professional supplier, has been engaged in steel business for more than ten years. We can provide a variety of steel products with high quality to our clients.

Q2: Can you provide OEM/ODM service?

A: Yes. Please feel free to contact us for more details.

Q3: What is your Payment Term?

A:One is 30% deposit by TT before production and 70% balance against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q4: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

Q5: Can you provide sample?

A: Yes. Sample is free for regular sizes, but the buyer needs to pay freight cost.

Q6: How long is your delivery time?

A: Our daily inventory is more than 8000 tons, so for common product size, we just need 5 days from stocks. If you would like to order product in special size, we need 20 to 30 days for new production.